This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

Probably the biggest risk of explosion and fire in the engineering industry is metal dust, especially where aluminum and its alloys are processed. When processing metal workpieces, dust is released, thus becomes very explosive when mixed with an oxidizing agent. Typical examples include aluminum, magnesium, titanium, or zinc, and their alloys.

During industrial production, small particles are dispersed into the air from the bulk material. As the air moves, the particles swirl and easily reach explosive concentrations. A dangerous explosion occurs when the combustible dust comes into contact with an initiation source. Especially in an enclosed space, the risk of explosion increases.

In most cases, it is a mechanical surface treatment, whether grinding, blasting, or cutting are the most explosion-prone areas of production. In the automotive industry, risk occurs in the production of aluminum wheels, alloy components, or during the production of brakes. In the engineering industry, for example, with the production of aluminum window profiles. CNC machines are prone to devastating fires, which can occur processing workpieces from alloys of metallic materials.

Metal powders have many specific characteristics that distinguish them from other organic powders, such as starch, flour, or sugar. Every dust changes its explosion parameters depending on the grain size. In the case of metal dust, this aspect is extremely significant. While for organic powders the difference in parameters between coarse and extremely fine dust is in the range of tens of percent, for aluminum dust it is in the number of hundreds of percent. So the rule is that the finer the metal dust, the more destructive the explosion.

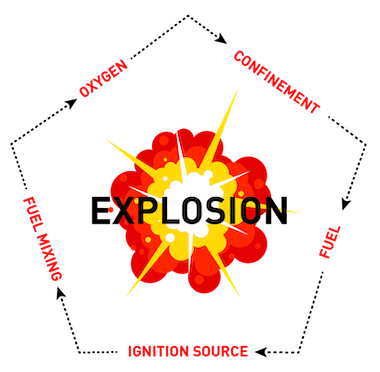

Ignition and subsequent explosion occur if the following conditions are met at the same time at the same space:

In industrial processing technology, which can normally consist of a spray dryer, a vibrating trough, a cyclone, etc., a chain reaction of explosions can be triggered under certain circumstances, because the individual technologies are interconnected by a pneumatic transport system. Underestimating the risk of separating the explosion with proper protection can have far-reaching consequences and even lead to the loss of human lives and the destruction of equipment and entire buildings.

At present, it is technologically possible to identify all imminent risks in advance. The obligation to apply appropriate preventive measures is imposed by the ATEX 153 directive, which achieves the protection of human lives and production technology from the devastating consequences of an explosion.

Not sure if the issue of explosion protection also applies to your company? Are you looking for a specific solution? Contact us as experts and manufacturers who are dealing with designing suitable explosion protection on daily basis.