This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

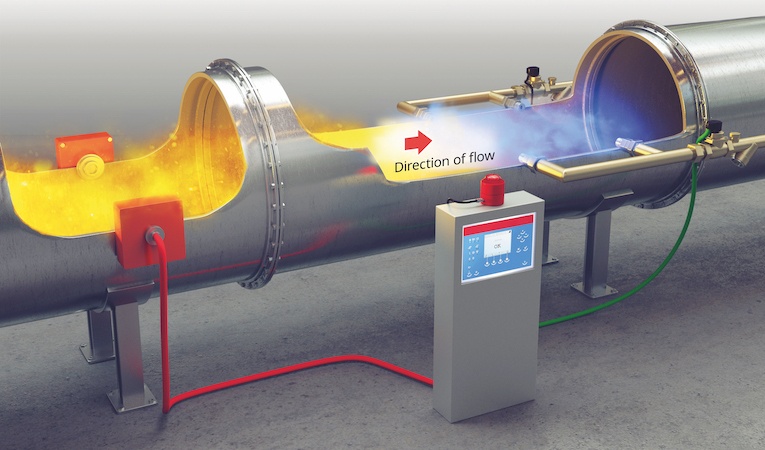

During some specific industrial processes, sparks and embers can be generated. These can be transported via airflow in the pipes or by conveyor belts. The problem starts when this particle reaches the filtration unit, cyclone, or silo. The transported material can start smouldering, which can lead to a fire or a destructive explosion. In order to minimize the risk of fire – to protect equipment and people and to reduce any downtime resulting from a fire, RSBP offers a solution with their spark extinguishing system.

The basis of the spark extinguishing system consists of highly sensitive detectors reacting in a few milliseconds to the presence of sparks in conveyor systems. If a spark or a fire appears, the control unit immediately receives an impulse from the detector, and the control unit activates the quick-opening valve releasing pressurized water. The extinguishing nozzle in the conveyor system creates a conical water mist, and the undesirable sparks or burning particles are extinguished. After the system effectively eliminates the danger, the system automatically switches to the standby position.

In a need of maintenance? Contact us.

Contact form