This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

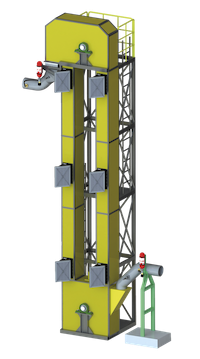

ELEVEX is an effective certified solution for the explosion protection of vertical and horizontal conveyors. The ELEVEX system reduces the explosion pressure to an extremely low level. Although the use of the ELEVEX system does not prevent the occurrence of an explosion in an elevator or other similar transport system, the consequences can be reduced to a minimum. The system is unique with its variability in use, where we can design it both for conveyors inside buildings and for those that are located outside. It can also be installed on your already operating technologies without any additional modifications. The ELEVEX system is certified according to the CEN/TR 16829.

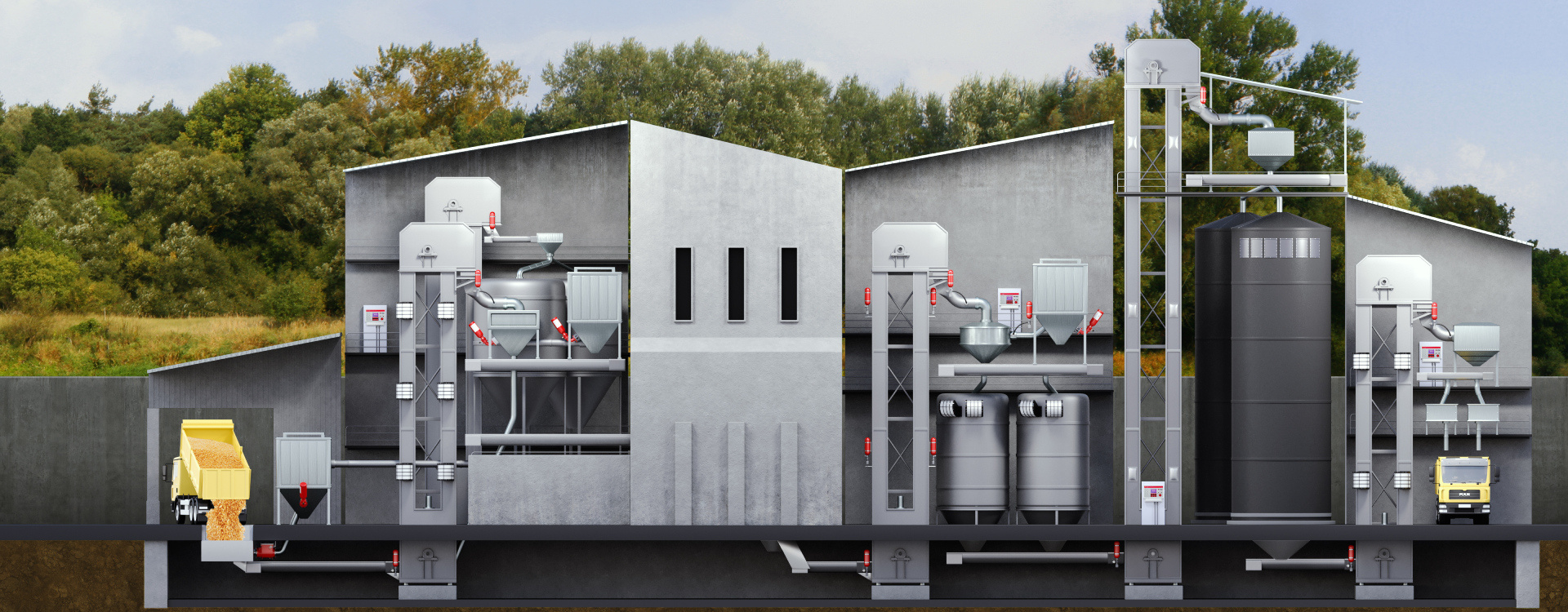

During the transport of bulk materials, there is a high risk of explosion because of the complexity of the process. In event of an explosion, the damage is done not only to property but also to human health. Consequences from the explosion are associated with not only high costs for repair or replacement of the technology but the whole production line can be completely suspended or delayed due to more complex handling of transported material during limited production.

Explosion suppression is the most common and widespread method of explosion protection for bucket elevators.

The main purpose of explosion venting is that the flame and pressure wave will be released through the venting panels into a safe zone.

The flameless explosion venting device FLEX prevents the spread of flame, thermal fronts and at the same time reduces pressure in the protected equipment.

Malthouses are an integral part of the food industry. This following case study will show you all risk areas, including the selection of the most suitable explosion protection designed by RSBP.

In a need of maintenance? Contact us.