This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

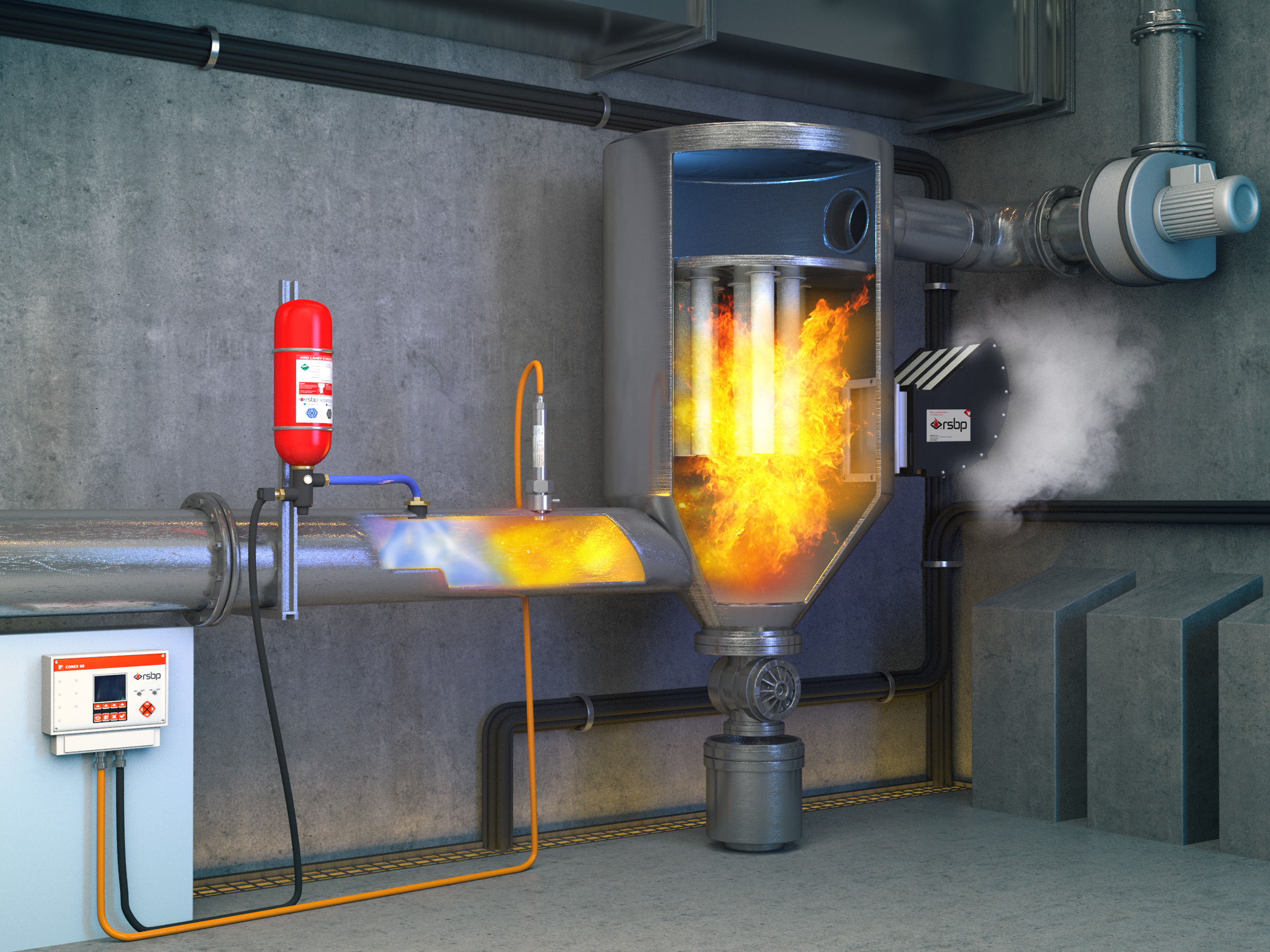

The HRD barrier is an active system that prevents the transmission of an explosion. It releases the extinguishing agent extremely fast into the pipeline and thus stops the increase in pressure. The HRD barrier can also isolate an explosion of dust classified as St 2 dust, light metal dust, gases, and hybrid mixtures. Specially developed pressure and optical detectors constantly monitor the protected zones of the production technology. The DetEx pressure detector and the LumEx 1 or LumEx 4 optical detectors can be used for detection. Activation of the HRD barrier is also possible via the VENT PRO explosion venting device. If an explosion is detected, the detectors transmit a signal to the control unit, which activates the HRD container units. These are equipped with quick-opening valves capable of immediate release of the extinguishing agent into the protected space and thus creating an effective extinguishing barrier. The HRD barrier suitably complements the HRD explosion suppression system used to protect devices. The appropriate combination of these two systems efficiently prevents property damage and protects human lives. This explosion isolation system is certified according to EN 15089 standard.

Mostly during the transportation of bulk material in pipelines that connects individual parts of the production technology. Initiation (e.g. hot surface, friction, a spark from equipment failure, etc.) can be easily formed, which in combination with flowing air and transported material creates a highly explosive mixture. During an explosion, a pressure wave first blasts through the pipe, followed by a flame. When transferred to subsequent parts of the production technology, secondary explosions may occur, which can have even more devastating consequences due to the turbulence created in the piping system.

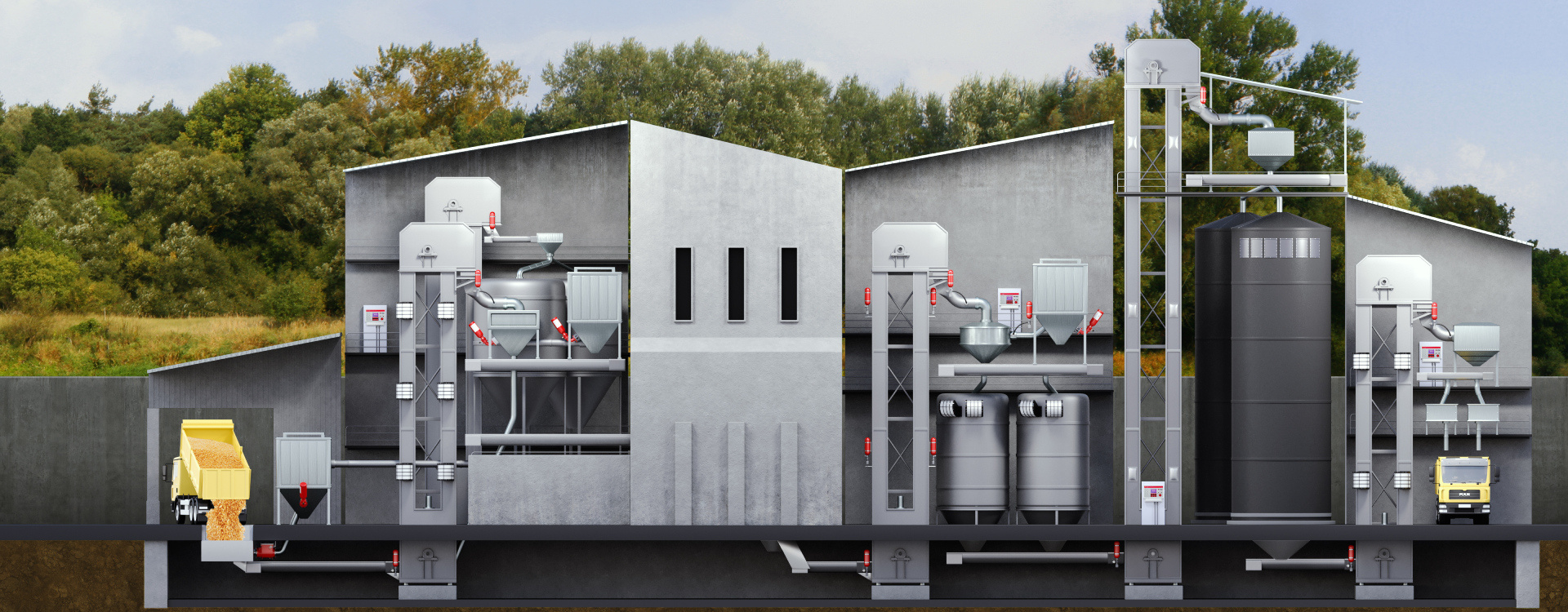

Malthouses are an integral part of the food industry. This following case study will show you all risk areas, including the selection of the most suitable explosion protection designed by RSBP.

In a need of a maintenance? Contact us.