This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

The HRD system is a certified active explosion suppression system. Highly sensitive detectors can detect an explosion in a matter of milliseconds. The system then opens the valves of the HRD container unit and the pressure of the fire extinguisher pulls out special telescopic nozzles, which ensure efficient dispersion of the fire extinguisher into the entire protected area.

Thanks to the HRD system, the increase in explosion pressure is under control - below the limit of the pressure resistance of the protected device, thus securing it against destruction. To effectively protect the entire technology, it is appropriate to supplement the HRD system with an HRD barrier, which prevents the transmission of the explosion to subsequent parts of the technology. The HRD system is certified according to the EN 14373.

|

RSBP's HRD Dry Chemical Explosion Suppression System is FM Approved per Approval Standard 5700. |

In industrial plants, there is a risk of explosion of dust, gas, flammable liquids, and their mixtures. The highest risk is in the food and pharmaceutical industry where, with regard to hygienic standards, only certain types of explosion protection equipment can be installed. The risk of endangering human life or health by explosion arises in case of increased movement of personnel around the production technology.

Pressure detectors constantly monitor operating conditions and are able to immediately detect an early explosion. They transmit this information within milliseconds to the control panel. The advantage is the short reaction time and the variability of use.

A dual or multi-zone control unit is a key part of the whole system. It evaluates, storages information from detectors, sends a signal to apply fire extinguisher to a protected area and provides data to superior systems. It serves as a user interface for the operating personnel.

Special HRD container unit, equipped with a quick-opening valve and other accessories. They keep the fire extinguisher under constant pressure. If an explosion is detected, they ensure the immediate and effective induction of the extinguishing medium into the protected equipment. The advantage is the variability of the size of the HRD container unit (8, 20, or 50 liters), fast and effective explosion suppression in its initial phase, easy handling, and simple maintenance.

Specially developed for technologies where suppression with extinguishing powder is not possible. WATER SHOT is a special HRD container unit equipped with a quick-opening valve and other accessories, which uses H2O extinguishing in place of the usual fire extinguisher.

WATER SHOT is designed to protect technologies, especially in the food industry, where explosion suppression with extinguishing powder is not acceptable. It is primarily intended for the protection of equipment that is cleaned with water in the normal process.

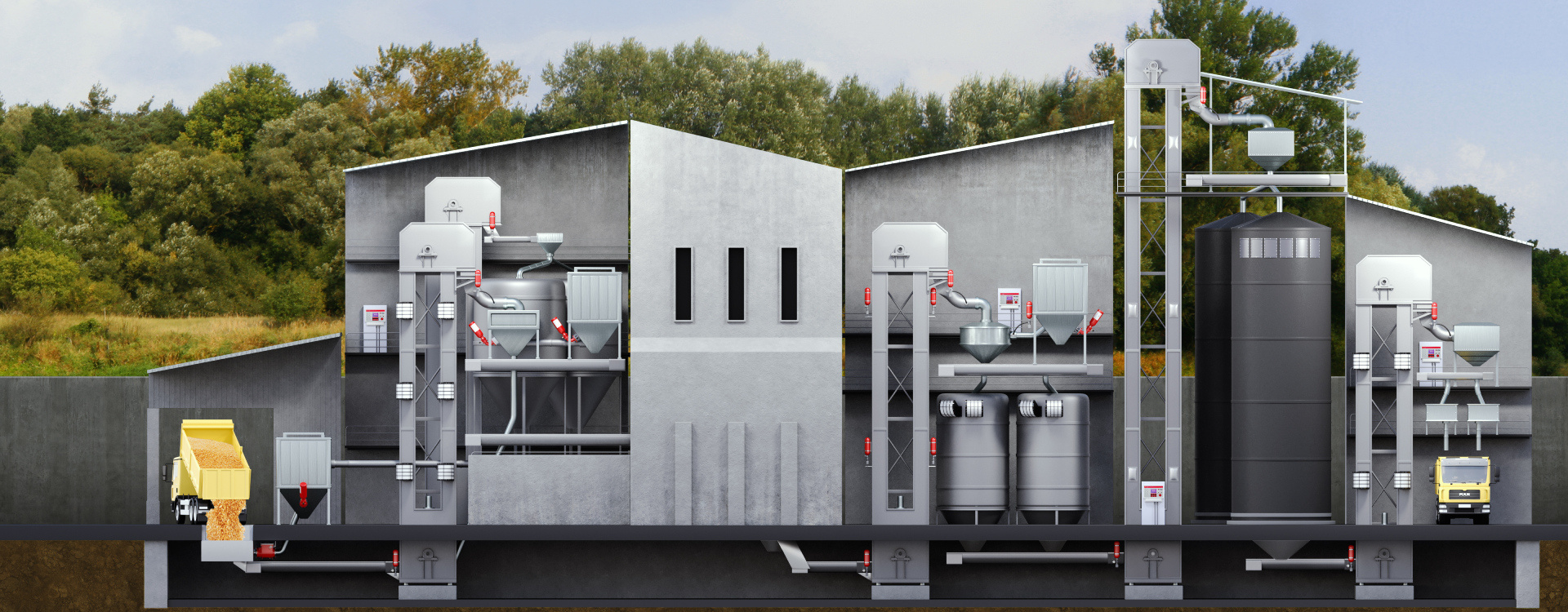

Malthouses are an integral part of the food industry. This following case study will show you all risk areas, including the selection of the most suitable explosion protection designed by RSBP.

In a need of maintenance? Contact us.