Tato stránka využívá soubory cookies za účelem zkvalitňování služeb a personalizaci nabídky zákazníkům v souladu s ochranou osobních údajů. Nastavení cookies si můžete upravit. Zavřít

Protiexplozní membrána značky RSBP je perfektním ekonomickým řešením ochrany před vznikem škod a ztrát ve výrobě. Za běžných provozních podmínek je odlehčovací otvor na technologickém zařízení překryt protiexplozní membránou. Při překročení provozní úrovně tlaku uvnitř zařízení dojde na jeho plášti k otevření zařízení pro odlehčení výbuchu a tím uvolnění tlaku a plamene z chráněného prostoru. Technologie je tak vystavena tlaku nižšímu, než je její tlaková odolnost, a proto nedojde k její destrukci. Efektivní odlehčení výbuchu prachu včetně lehkých kovů, plynu i hybridní směsi. Membrány VENT PRO jsou certifikovány v souladu s normou EN 14797.

Skladování a manipulace s prachy v průmyslu jsou mnohdy spojeny s reálným nebezpečím výbuchu. Stačí jiskra od zkratu v elektroinstalaci, žhavý předmět, který se do technologického celku dostane společně s materiálem, nebo prosté nedodržení bezpečnosti práce - následky mohou být nedozírné. Riziko výbuchu vzniká nejen při manipulaci s prachem, ale také plynem, párou a hybridní směsí.

DivEx je příslušenství k zařízení pro odlehčení výbuchu VENT PRO. Omezuje úhel otevření VENT PRO a usměrňuje výbuchovou tlakovou vlnu a plamen do požadovaného bezpečného prostoru. Zmenšuje nebezpečnou zónu kolem zařízení pro odlehčení výbuchu a zvětšuje použitelný provozní prostor.

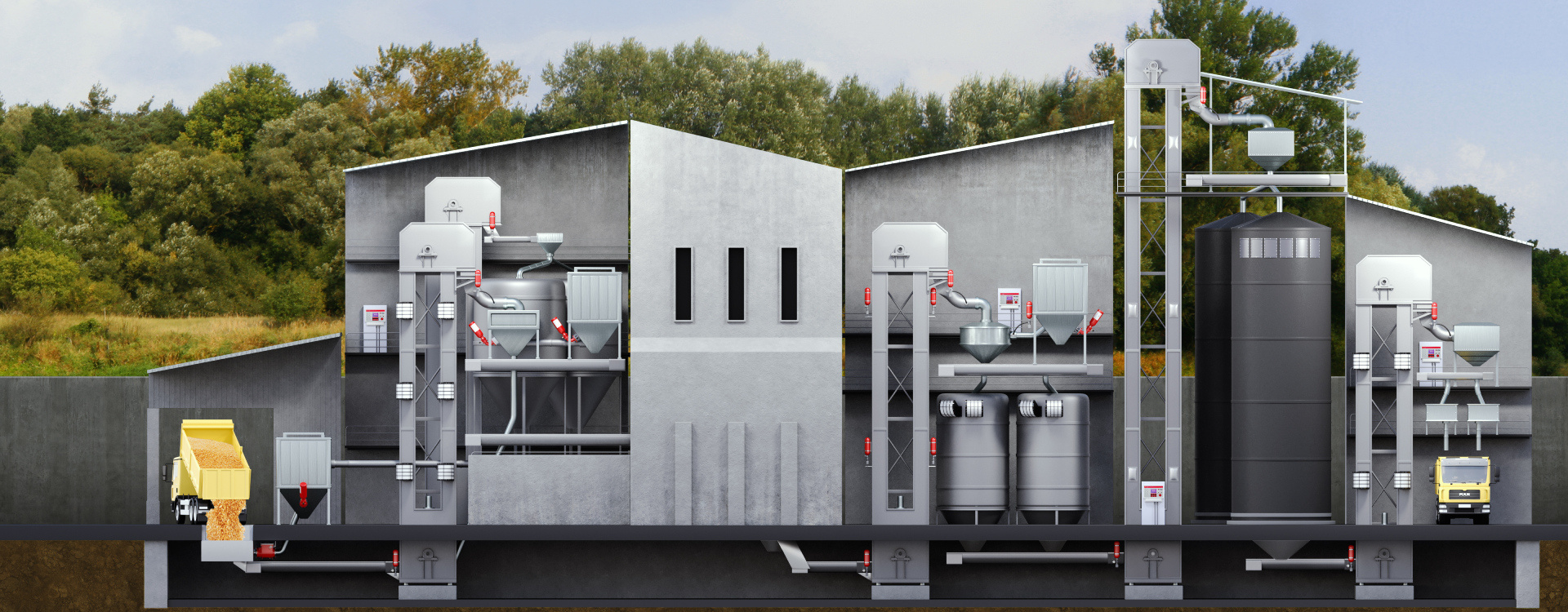

Sladovny jsou nedílnou součástí potravinářského průmyslu. Vypracovaná studie RSBP vám ukáže všechny rizikové oblasti, včetně výběru té nejvhodnější ochrany. V modelové situaci jsme znázornili příklady použití VENT PRO - zařízení pro odlehčení výbuchu.

| Rozměr | Odlehčovací plocha (m2) | A - vnější rozměr (mm) | B - vnější rozměr (mm) |

| 229 x 229 F | 0,05 | 309 | 309 |

| 229 x 305 F | 0,06 | 309 | 385 |

| 260 x 260 F | 0,07 | 337 | 337 |

| 170 x 470 F | 0,08 | 250 | 550 |

| 220 x 540 F | 0,12 | 308 | 628 |

| 270 x 458 F | 0,12 | 350 | 538 |

| 305 x 457 F | 0,14 | 390 | 542 |

| 300 x 500 F | 0,15 | 382 | 589 |

| 410 x 410 F | 0,17 | 490 | 490 |

| 241 x 762 F | 0,18 | 331 | 852 |

| 630 x 310 F | 0,19 | 385 | 705 |

| 580 x 410 F | 0,24 | 500 | 670 |

| 490 x 590 F | 0,28 | 573 | 673 |

| 610 x 470 F | 0,29 | 550 | 690 |

| 600 x 600 F | 0,35 | 656 | 656 |

| 450 x 800 F | 0,36 | 550 | 900 |

| 610 x 610 F | 0,37 | 690 | 690 |

| 500 x 750 F | 0,38 | 580 | 830 |

| 457 x 890 F | 0,39 | 537 | 970 |

| 586 x 920 F | 0,53 | 671 | 1005 |

| 588 x 908 F | 0,53 | 680 | 1000 |

| 800 x 800 F | 0,62 | 850 | 850 |

| 685 x 1100 F | 0,75 | 765 | 1178 |

| 870 x 910 F | 0,79 | 960 | 1000 |

| 920 x 920 F | 0,83 | 1005 | 1005 |

| 915 x 1118 F | 1,02 | 1000 | 1203 |

| 1020 x 1020 F | 1,03 | 1106 | 1106 |

| 1118 x 1118 F | 1,25 | 1202 | 1202 |

| 1130 x 1130 F | 1,28 | 1220 | 1220 |

| 1000 x 2000 F | 2,00 | 1090 | 2090 |

| Rozměr | Odlehčovací plocha (m2) | A - vnější rozměr (mm) | B - vnější rozměr (mm) |

| 229 x 229 D | 0,05 | 309 | 309 |

| 260 x 260 D | 0,06 | 340 | 340 |

| 150 x 600 D | 0,08 | 220 | 670 |

| 220 x 540 D | 0,11 | 300 | 620 |

| 305 x 457 D | 0,12 | 375 | 527 |

| 610 x 290 D | 0,16 | 365 | 685 |

| 630 x 310 D | 0,18 | 385 | 705 |

| 490 x 590 D | 0,27 | 565 | 665 |

| 450 x 800 D | 0,34 | 530 | 880 |

| 586 x 920 D | 0,51 | 661 | 995 |

| 2 x 610 x 290 D | 0,32 | 385 | 1385 |

| 2 x 630 x 310 D | 0,35 | 385 | 1385 |

| 920 x 920 D | 0,81 | 995 | 995 |

| 915 x 1118 D | 0,98 | 990 | 1193 |

| 1020 x 1020 D | 1 | 1095 | 1095 |

| Rozměr | Odlehčovací plocha (m2) | A - vnější rozměr (mm) | B - vnější rozměr (mm) |

| 229 x 229 S | 0,05 | 309 | 309 |

| 260 x 260 S | 0,07 | 340 | 340 |

| 220 x 540 S | 0,12 | 300 | 620 |

| 305 x 457 S | 0,14 | 390 | 542 |

| 340 x 440 S | 0,15 | 400 | 500 |

| 610 x 290 S | 0,17 | 365 | 685 |

| 630 x 310 S | 0,19 | 385 | 705 |

| 490 x 590 S | 0,28 | 565 | 665 |

| 450 x 800 S | 0,36 | 530 | 880 |

| 578 x 851 S | 0,47 | 658 | 931 |

| 586 x 920 S | 0,53 | 661 | 995 |

| 920 x 920 S | 0,84 | 995 | 995 |

| 851 x 1162 S | 0,98 | 931 | 1242 |

| 915 x 1118 S | 1,01 | 990 | 1193 |

| 1020 x 1020 S | 1,01 | 1095 | 1095 |

| 1130 x 1130 S | 1,28 | 1220 | 1220 |

| Rozměr | Odlehčovací plocha (m2) | A - vnější rozměr (mm) | B - vnější rozměr (mm) |

| 229 x 229 T | 0,04 | 309 | 309 |

| 260 x 260 T | 0,05 | 340 | 340 |

| 220 x 540 T | 0,1 | 300 | 620 |

| 305 x 457 T | 0,11 | 375 | 527 |

| 610 x 290 T | 0,14 | 365 | 685 |

| 630 x 310 T | 0,16 | 385 | 705 |

| 490 x 590 T | 0,24 | 565 | 665 |

| 2 x 610 x 290 T | 0,28 | 385 | 1385 |

| 450 x 800 T | 0,32 | 530 | 880 |

| 2 x 630 x 310 T | 0,35 | 385 | 1405 |

| 586 x 920 T | 0,48 | 661 | 995 |

| 920 x 920 T | 0,78 | 995 | 995 |

| 915 x 1118 T | 0,95 | 990 | 1193 |

| 1020 x 1020 T | 0,96 | 1092 | 1095 |

| Rozměr | Odlehčovací plocha (m2) | D1 - vnitřní rozměr vydutí (mm) | D2 - roztečná kružnice (mm) | D3 - vnější rozměr (mm) |

| DN 250 T | 0,05 | 265 | 320 | 345 |

| DN 300 T | 0,06 | 315 | 350 | 375 |

| DN 350 T | 0,07 | 340 | 387 | 420 |

| DN 400 T | 0,10 | 390 | 443 | 475 |

| DN 450 T | 0,13 | 445 | 486 | 525 |

| DN 510 T | 0,16 | 505 | 550 | 585 |

| DN 600 T | 0,24 | 595 | 646 | 675 |

| DN 630 T | 0,27 | 625 | 680 | 705 |

| DN 750 T | 0,41 | 765 | 817 | 845 |

| DN 800 T | 0,47 | 815 | 860 | 895 |

| DN 880 T | 0,53 | 875 | 920 | 955 |

| DN 900 T | 0,57 | 895 | 955 | 995 |

| DN 1000 T | 0,72 | 995 | 1060 | 1095 |

| DN 1100 T | 0,87 | 1095 | 1160 | 1195 |

DivEx

| Version | Vent panel VENT PRO | Kst.max [bar.m/s] | Pred.max [bar] | Venting effciency [%] | Weight [kg] |

| DivEx var. 1 | 170×470 150×600 220×540 |

200-320 | 0.7-1.2 | >65-70 | 4.0 |

| DivEx var. 2 | 270×458 610×290 241×762 630×310 |

200-320 | 0.7-1.2 | 65-80 | 5.1 |

| DivEx var. 3 | 305×457 340×440 300×500 |

200-320 | 0.7-1.2 | 70-80 | 5.2 |

| DivEx var. 4 | 490×590 610×610 450×800 578×851 |

200-320 | 0.7-1.2 | 70-80 | 15.0 |

| DivEx var. 6 | 586×920 685×1100 |

200-320 | 0.6-1.0 | 70-80 | 14.7 |

| DivEx var. 7 | 870×910 851×1162 |

200-320 | 0.6-1.0 | 65-70 | 25.0 |

| DivEx var. 8 | 920×920 1020×1020 915×1118 |

200-320 | 0.6-0.9 | 65-70 | 28.3 |

Zařízení již máte, ale potřebujete servis? Napište nám.