This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

Power plants processing coal and biomass are more accident-prone by an increased risk of explosion. During the production of energy, both thermal and electrical, explosive dust concentrations can occur in the production process. Ideal conditions created in closed space, such as the presence of an ignition source, the optimal concentration of combustible dust, and oxidizing agents, will initiate the explosion. Which endangers human health and lives and poses a high risk of destructive damage to property.

Potential places of explosive dust concentrations are external and internal coaling areas of heating plants or power plants. When transporting coal from a coal dump to other parts of the production process, explosive mixtures may form. Coal travels through coal roads, sorters, cyclones, mills, and tanks to the boiler. A combustible mixture of coal powder and air can form everywhere, and there is a high risk of a devastating explosion.

A similar risk also arises in heating plants and biomass power plants. Biofuels require the drying of larger organic particles, which are later crushed into lighter particles. Also, in this situation, an explosive mixture of dust particles and air can form and become dangerous.

The influence parameters for the formation of an explosive mixture are the humidity of the coal product, its temperature, the oxygen content in the carrier medium, and the grain size. In general, we can say that if the moisture content of the coal is low, the temperature of the carrier medium is higher and the grain size of the coal is smaller, the risk for the explosion to occur is higher. Therefore, it is necessary to pay increased attention to these technologies during design and operation. When burning a mixture of coal and biomass (straw, husks, wood pulp, etc.), the minimum ignition temperature of this mixture must also be taken into account.

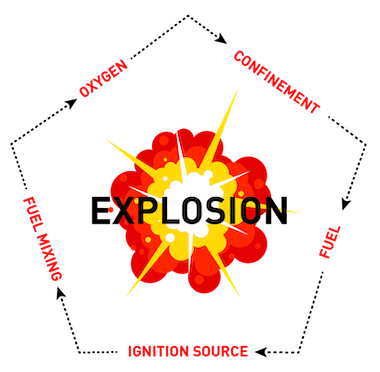

Ignition and subsequent explosion occur if the following conditions are met at the same time in the same space:

Failure to respect the hazards involved in transporting the processed material to the boilers can, in certain circumstances, trigger a chain reaction of explosions across technologies and the entire energy plant. A seemingly single explosion will turn into multiple subsequent explosions with far-reaching consequences. This chain reaction can even lead to the loss of human lives and the destruction of equipment and entire buildings.

At present, it is technologically possible to identify all imminent risks in advance. The obligation to apply appropriate preventive measures is imposed by the ATEX 153 directive, which achieves the protection of human lives and production technology from the devastating consequences of an explosion.

Not sure if the issue of explosion protection also applies to your company? Are you looking for a specific solution? Contact us as experts and manufacturers who are dealing with designing suitable explosion protection on daily basis.