Tato stránka využívá soubory cookies za účelem zkvalitňování služeb a personalizaci nabídky zákazníkům v souladu s ochranou osobních údajů. Nastavení cookies si můžete upravit. Zavřít

Inovovaná klapka pro oddělení výbuchu B-FLAP I PRO, byla certifikována dle norem EN 16447 a EN 15089. Naše klapky byly testovány na jedné z nejmodernějších akreditovaných laboratoří s ohledem na reálné podmínky použití v průmyslových provozech.

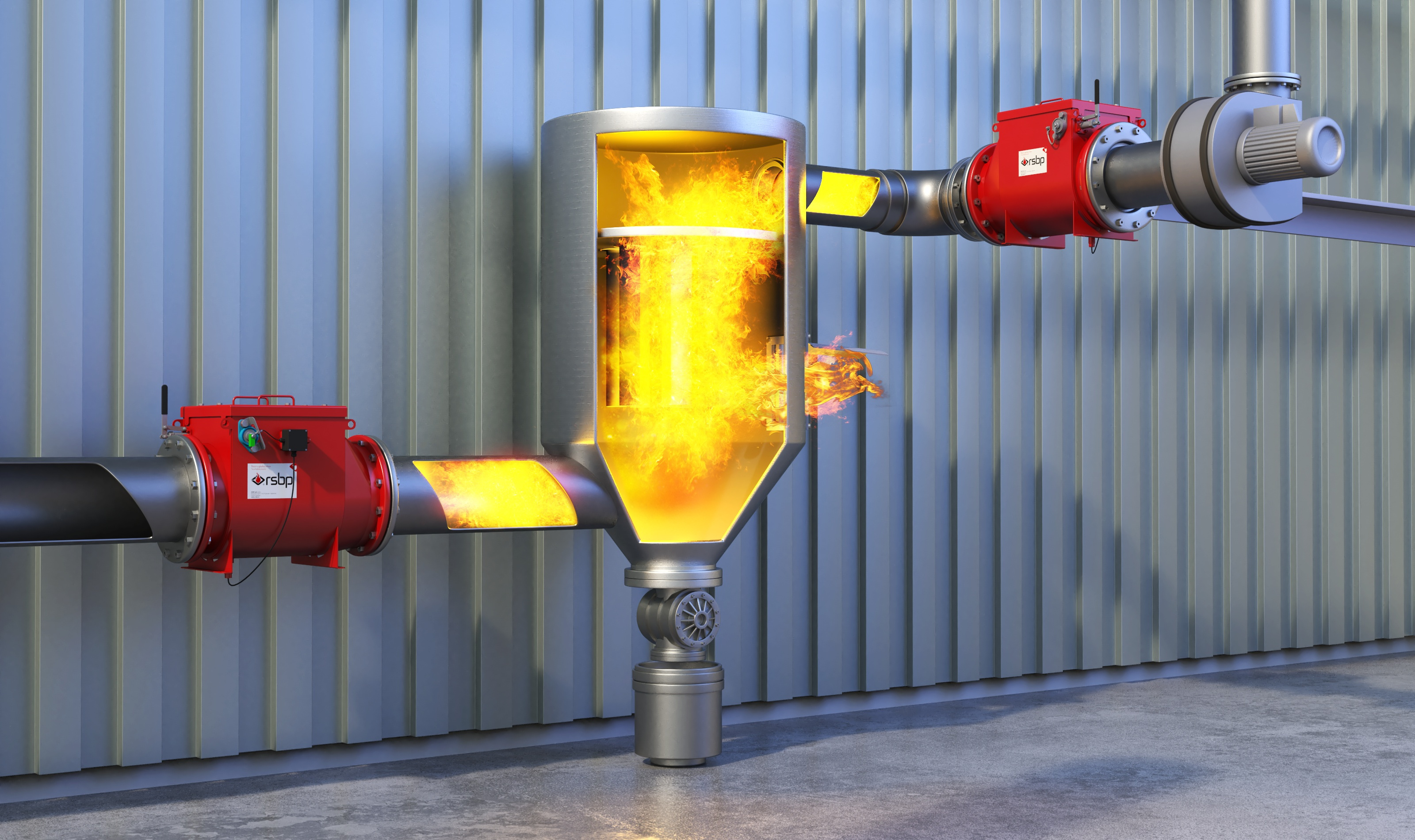

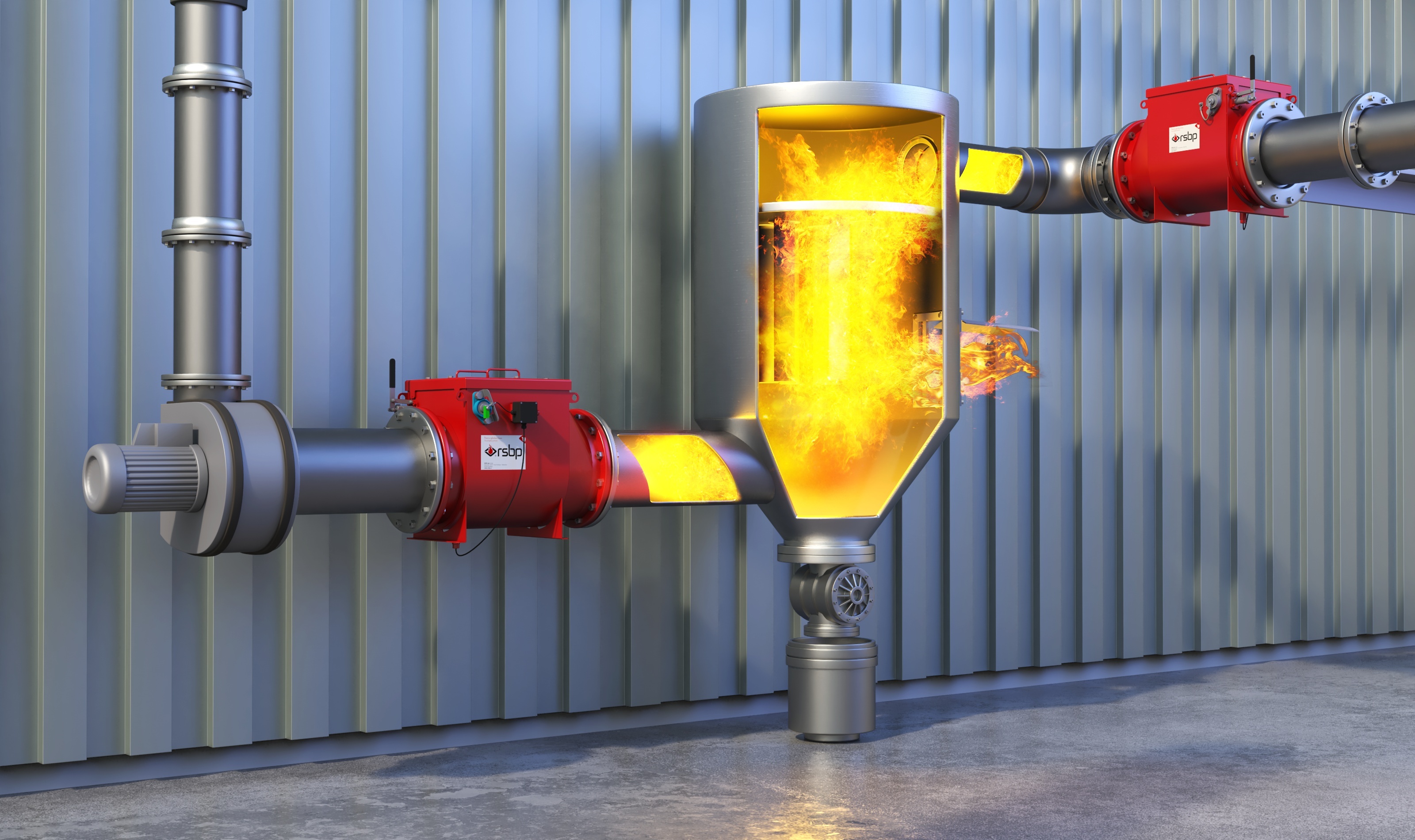

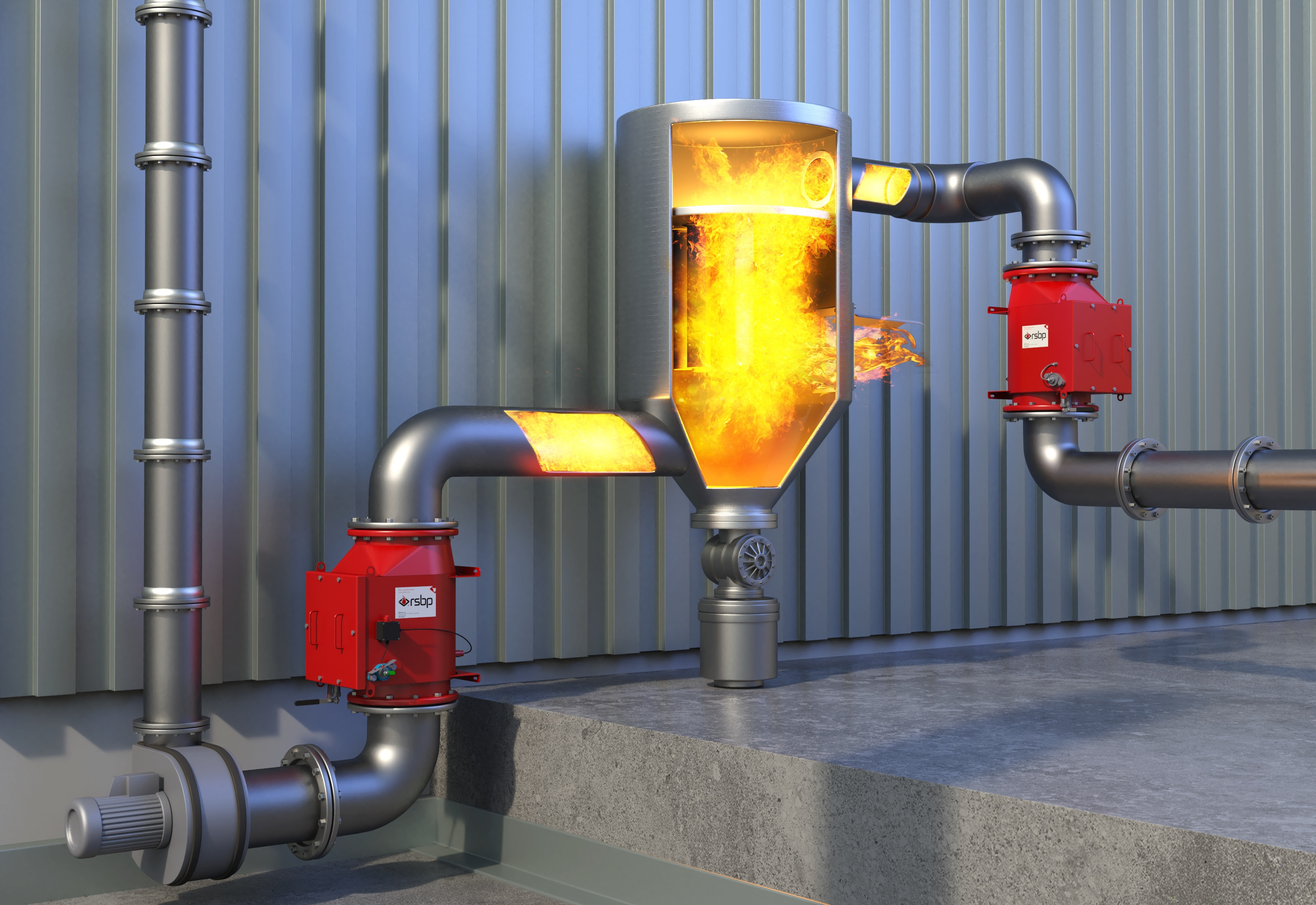

Novinkou jsou rozšířené možnosti instalace zpětné klapky. Podle platných norem je možné klapku instalovat jak do horizontálního i do vertikálního potrubí. Použití je možné do tažných (pull) i tlačných (push) aspiračních systémů. B-FLAP I PRO je rovněž možné instalovat na potrubní trasy obsahující překážky a nebo kolena mezi chráněným zařízením a místem instalace zpětné klapky. Novinkou je rovněž zvýšení tlakové odolnosti (pmax) klapky, zvýšení maximálního redukovaného tlaku (pred,max) v chráněném zařízení, ze kterého se případná exploze šíří. Podle nejnovějších zkoušek a certifikace se zkrátila minimální a prodloužila maximální instalační vzdálenost od chráněného zařízení.

Zpětnou protiexplozní klapku B-FLAP I PRO lze použít k izolaci výbuchu organických, lepivých, spékavých a kovových prachů, a to až do třídy výbušnosti St 3, a prachy s velmi nízkými hodnotami minimální iniciační energie a teploty (MIE a MIT). Facelift protiexplozní klapky s sebou přinese rovněž jednodušší manipulaci při instalaci, nastavení a provozní údržbě.

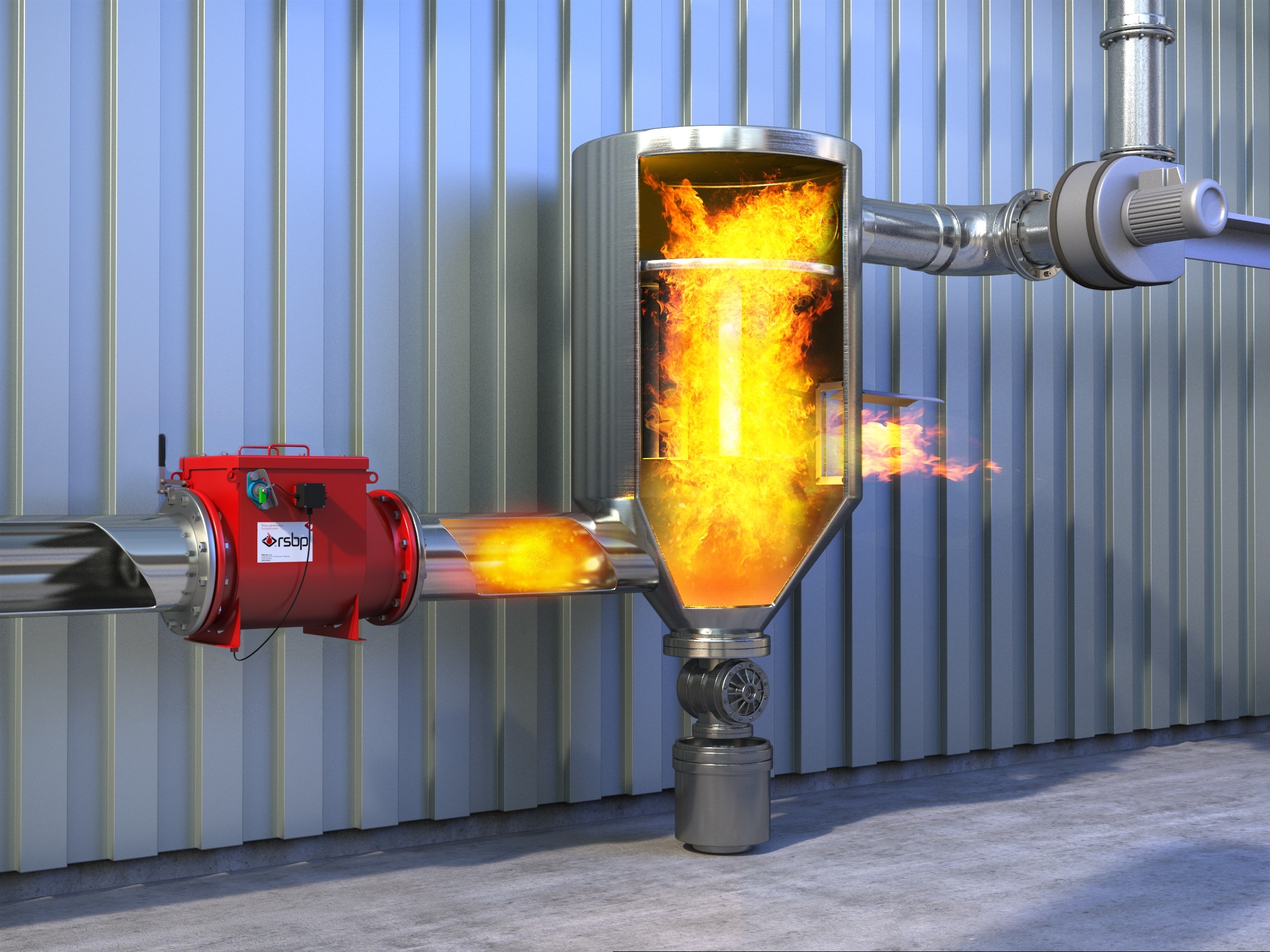

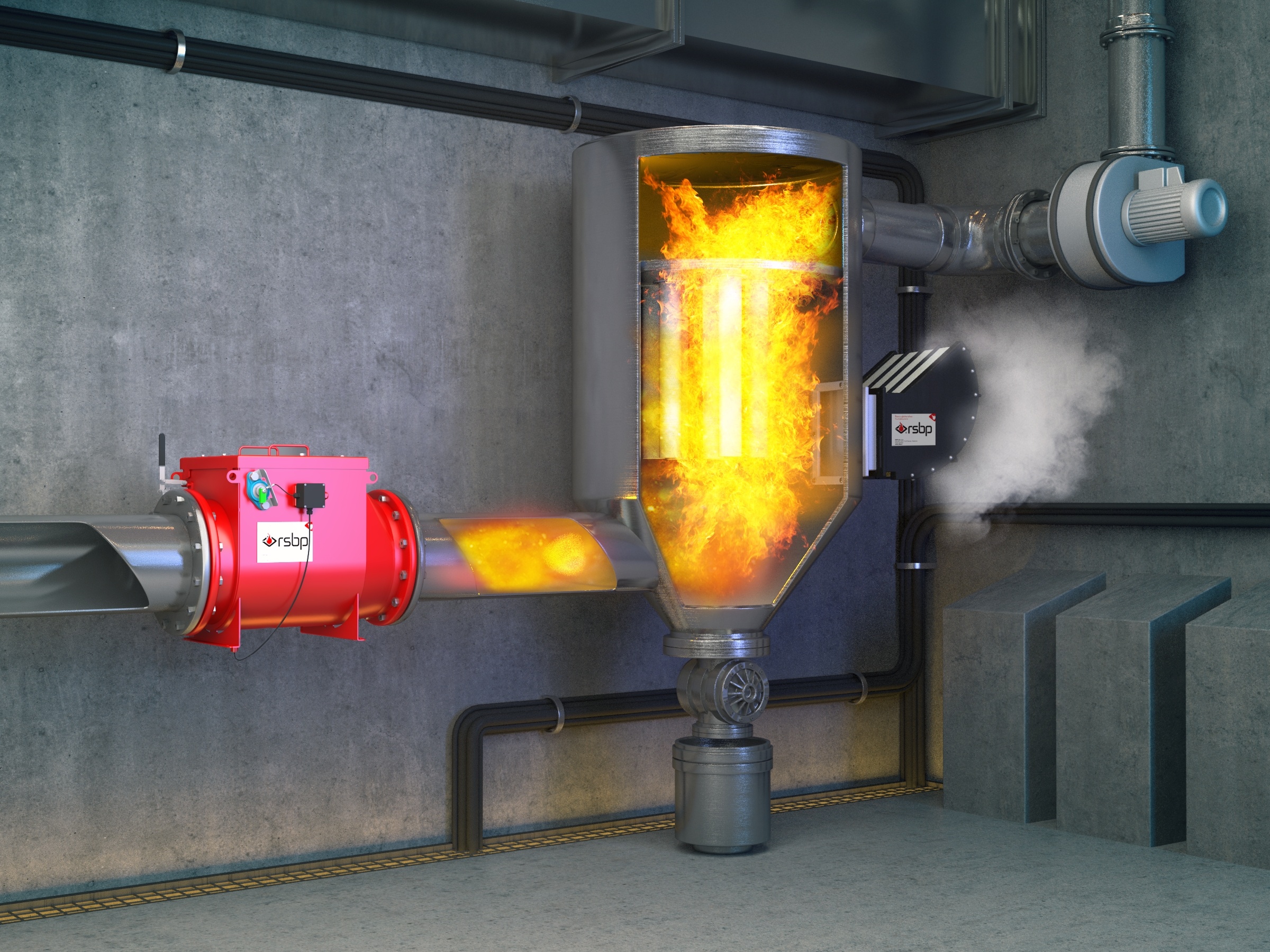

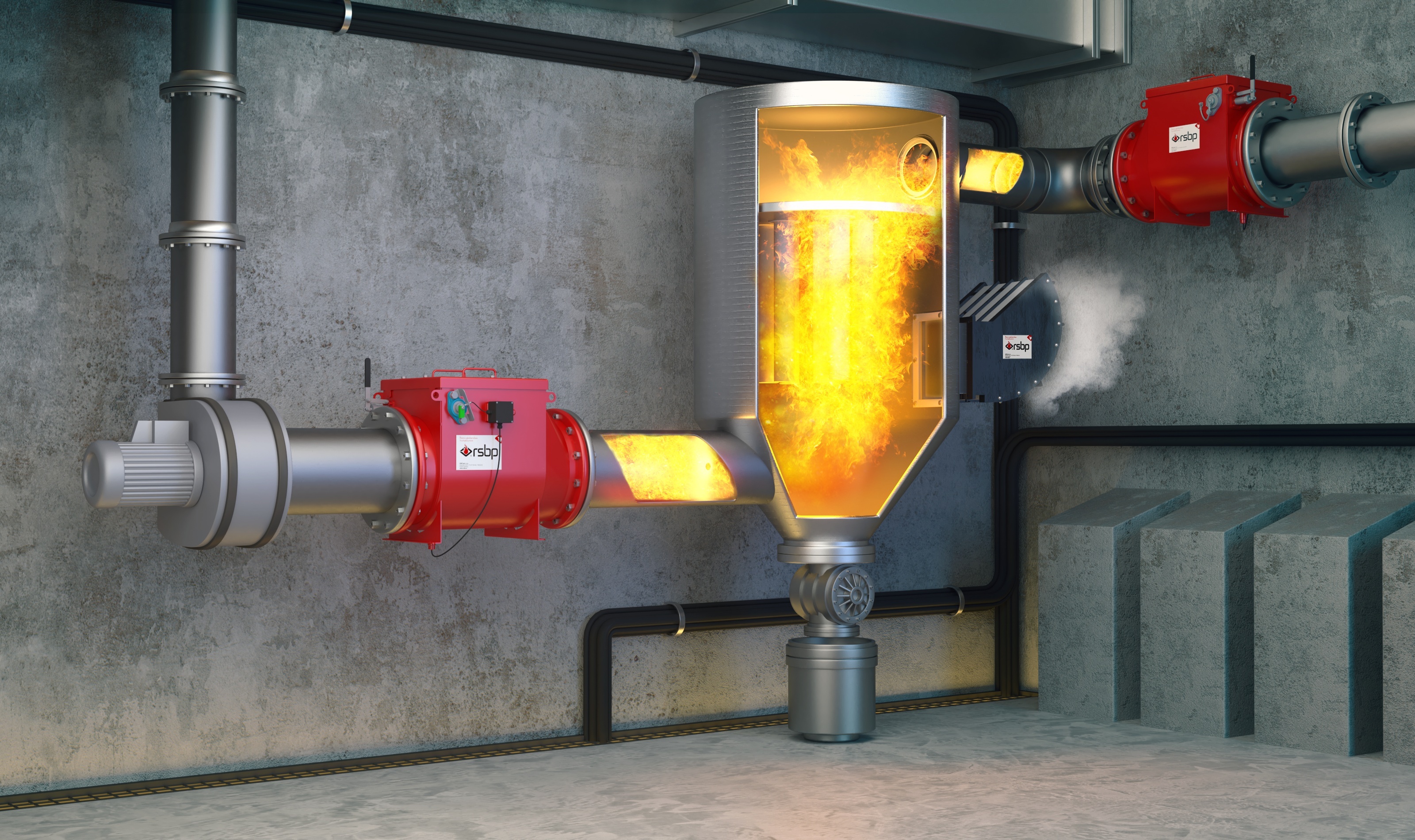

Zpětná klapka zákazníkovi nabízí efektivní zabránění přenosu exploze mezi propojenými částmi průmyslové technologie. Klapka izoluje výbuch po celé potrubní trase odsávacích systému, je tedy vhodná nejen pro zabránění přenosu exploze na vstupu do filtru nebo cyklónu, ale také pro izolaci výbuchu na výstupním potrubí z filtračních systémů (tzv. čistá stranu filtru), na přísávacím potrubí do mlýnu, na vletu materiálu do sušáren a dalších podobných zařízení.

Klapka pro oddělení výbuchu B-FLAP I PRO je mechanické zařízení navržené tak, aby během výbuchu zabránilo přenosu plamene a tlaku mezi technologiemi. V případě běžného provozu je zpětná protiexplozní klapka držena v otevřeném stavu pomocí mechanismu RPD, toto řešení výrazně snižuje tlakové ztráty v potrubním systému. V případě výbuchu dojde k jejímu uzavření a uzamčení. Spolu s dalšími bezpečnostními prvky tvoří naše zpětná klapka účinný systém pro ochranu technologických celků. Nejčastěji se B-FLAP I PRO používá v kombinaci se zařízení pro odlehčení výbuchu - VENT PRO nebo FLEX. Klapka pro oddělení výbuchu je vhodná pro potrubí o průměru DN 100 - DN 800.

Pokud ve vaší technologii používáte pneudopravu, potrubí s průměrem menším než DN 100, máte technologii zkonstruovanou na maximální výbuchový tlak, případně kratší instalační vzdálenosti, než jsou nutné k instalaci zpětné klapky, podívejte se na GatEx nebo HRD bariéru.

Do potrubní trasy odsávacích systémů může být snadno zavlečena iniciace (například horký povrch, tření, jiskra z poruchy zařízení, apod.), která v kombinaci s proudícím vzduchem a dopravovaným materiálem tvoří výbušnou směs. Tlaková vlna a plamen šířící se potrubním systémem může zasáhnout a tím zničit také návazující technologie nebo ohrozit osoby pohybující se v okolí.

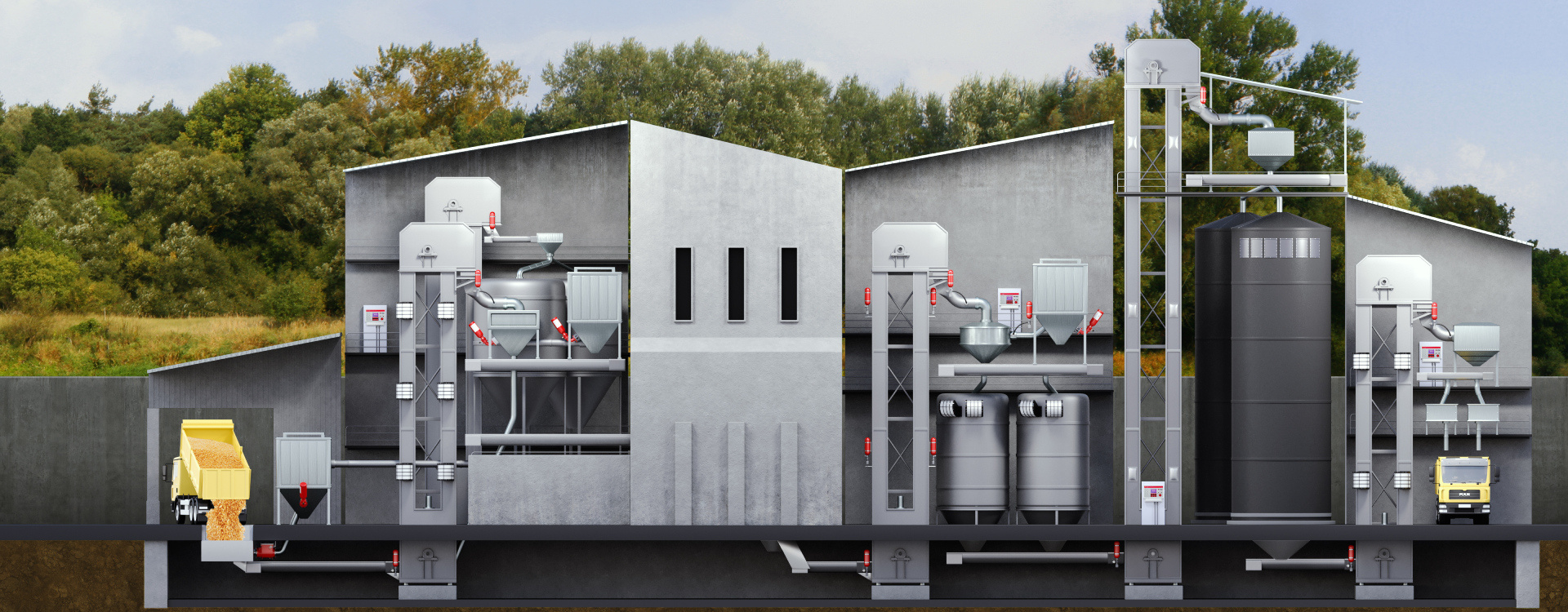

Sladovny jsou nedílnou součástí potravinářského průmyslu. Vypracovaná studie RSBP vám ukáže všechny rizikové oblasti, včetně výběru té nejvhodnější ochrany. V modelové situaci jsme znázornili příklady použití klapky pro oddělení výbuchu B-FLAP I PRO, která účinně zabraňuje přenosu výbuchu mezi jednotlivými částmi technologie.

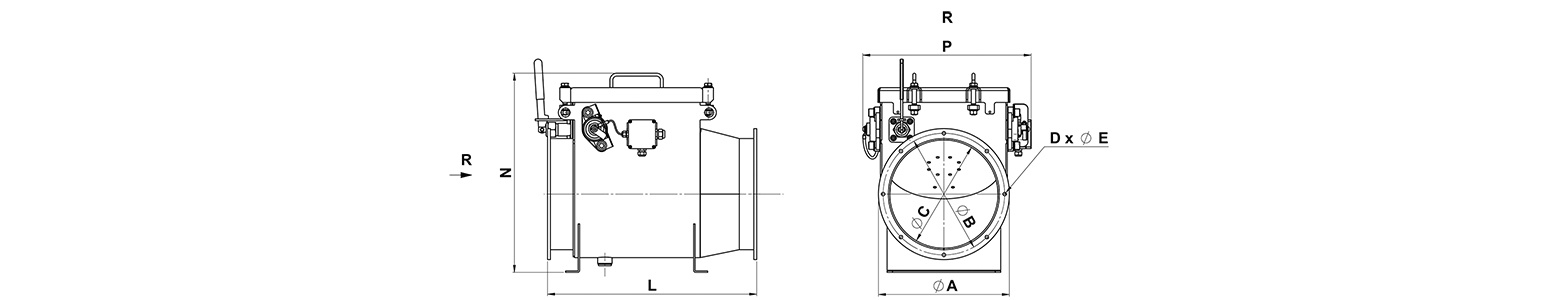

| Typ | ØA (mm) |

ØB (mm) |

ØC (mm) |

L (mm) |

N (mm) |

P (mm) |

Hmotnost (kg) |

| DN 100 | 152 | 132 | 100 | 280 | 287 | 244 | 9 |

| DN 125 | 177 | 157 | 125 | 305 | 308 | 269 | 11 |

| DN 150 | 202 | 182 | 150 | 330 | 337 | 294 | 13 |

| DN 200 | 253 | 233 | 200 | 390 | 387 | 344 | 18 |

| DN 250 | 303 | 283 | 250 | 510 | 502 | 417 | 41 |

| DN 280 | 343 | 317 | 280 | 560 | 537 | 447 | 48 |

| DN 300 | 363 | 337 | 300 | 580 | 552 | 467 | 51 |

| DN 315 | 378 | 352 | 315 | 600 | 567 | 482 | 54 |

| DN 355 | 418 | 392 | 355 | 630 | 607 | 522 | 62 |

| DN 400 | 464 | 438 | 400 | 695 | 652 | 568 | 73 |

| DN 450 | 514 | 488 | 450 | 750 | 702 | 619 | 88 |

| DN 500 | 564 | 538 | 500 | 800 | 752 | 669 | 101 |

| DN 560 | 664 | 629 | 560 | 930 | 838 | 745 | 157 |

| DN 630 | 734 | 698 | 630 | 1005 | 908 | 815 | 180 |

| DN 710 | 814 | 775 | 710 | 1156 | 1102 | 967 | 305 |

| DN 800 | 904 | 861 | 800 | 1246 | 1193 | 1057 | 351 |

Zařízení již máte, ale potřebujete servis? Napište nám.