This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

In the painting industry, various types of coating materials are processed and used. The most commonly used materials include liquid paints and powder paints. In both cases, there is a significant risk of fire or explosion.

Unlike liquid paints, where the individual components are mixed and reacted in a solution of water or solvent during production, the individual components of the powder paints are mixed in the melt. The final mixture is extruded by the production equipment on cooling rollers and, after cooling, is grounded in special mills to the required coarseness of the powder particles. This substance is the final product - powder paint.

The powder paint is not diluted or dissolved in any liquid for application. It is applied in powder form through compressed air, which, when mixed with the powder, forms a mixture that behaves as a liquid mixture. It can create a dangerous explosive atmosphere in paint booths, a danger that arises especially in filter units.

Fires and dust explosions in the paint industry can occur, for example, during grinding and crushing of the melt in the production of powder paint. The application of powder paints in paint booths also poses a great risk. During the painting process, dispersed dust is collected in filters, where it can create an explosive atmosphere. Electrostatic discharges on paint guns can also be a problem, where a fire can occur.

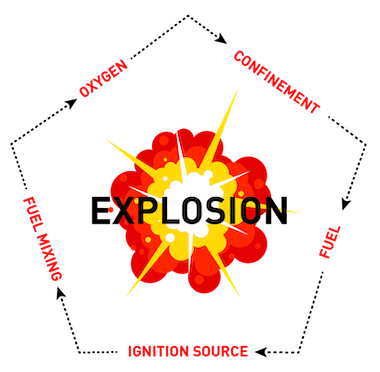

Ignition and subsequent explosion occur if the following conditions are met at the same time at the same space:

At present, it is technologically possible to identify all imminent risks in advance. The obligation to apply appropriate preventive measures is imposed by the ATEX 153 directive, which achieves the protection of human lives and production technology from the devastating consequences of an explosion.

Not sure if the issue of explosion protection also applies to your company? Are you looking for a specific solution? Contact us as experts and manufacturers who are dealing with designing suitable explosion protection on daily basis.