Diese Website verwendet Cookies, um die Qualität der Dienstleistungen zu verbessern und das Angebot für unsere Kunden in Übereinstimmung mit den Datenschutzrichtlinien zu personalisieren. Sie können Ihre Cookies-Einstellungen anpassen. Schließen

Dust. Particles whose size varies in units of micrometers. Dust clouds or settled combustible dust in combination with the initiation source and oxygen create a life-threatening situation. The explosion can permanently damage production lines or even other parts of the factory. For many industrial companies, dust is produced as the main product (e.g., flour, sugar, starch). Still, in other factories, dust is created as a form of waste from the production process (e.g., sawdust from wood production).

In most cases, the risk of an explosion cannot be ruled out through preventive measures, which is why explosion protection plays a crucial role in securing workplaces and protects not only property but also employees' health and lives. The most commonly used methods to minimize explosions' consequences include explosion venting, suppression, and lastly isolation, which prevents explosion transmission. In this article, you will find more detailed information about explosion isolation as one of the three methods to secure your company from airborne combustible dust explosions.

Explosion isolation prevents the transmission of an explosion between connected technologies. Production processes often vary according to the type of processed material, production process, and technologies used. A common factor is the pipelines that connect devices (for example, dryers, crushers, mills, filters, separators, and others) into one production unit. These pipe sections must be protected so that there is no transmission of pressure waves and flame fronts, which could irreversibly destroy the entire production line.

Explosion protection is specified in standards and other valid documents. The European standard EN 15089 deals with explosion isolation systems. According to this standard, explosion isolation is usually installed on a pipe between two vessels or just behind the vessel. It can be connected to detection devices and a control unit. Explosion isolation flap valves, which are also classified as explosion isolation devices, are also specified in more detail in standard EN 16447.

The purpose of explosion isolation is to prevent the spread of an explosion created in a protected vessel. RSBP products are designed to stop a flame and pressure wave simultaneously, which causes complete separation of an explosion from connected technology. The resulting flame front is stopped at an initial stage using detection associated with blocking or extinguishing.

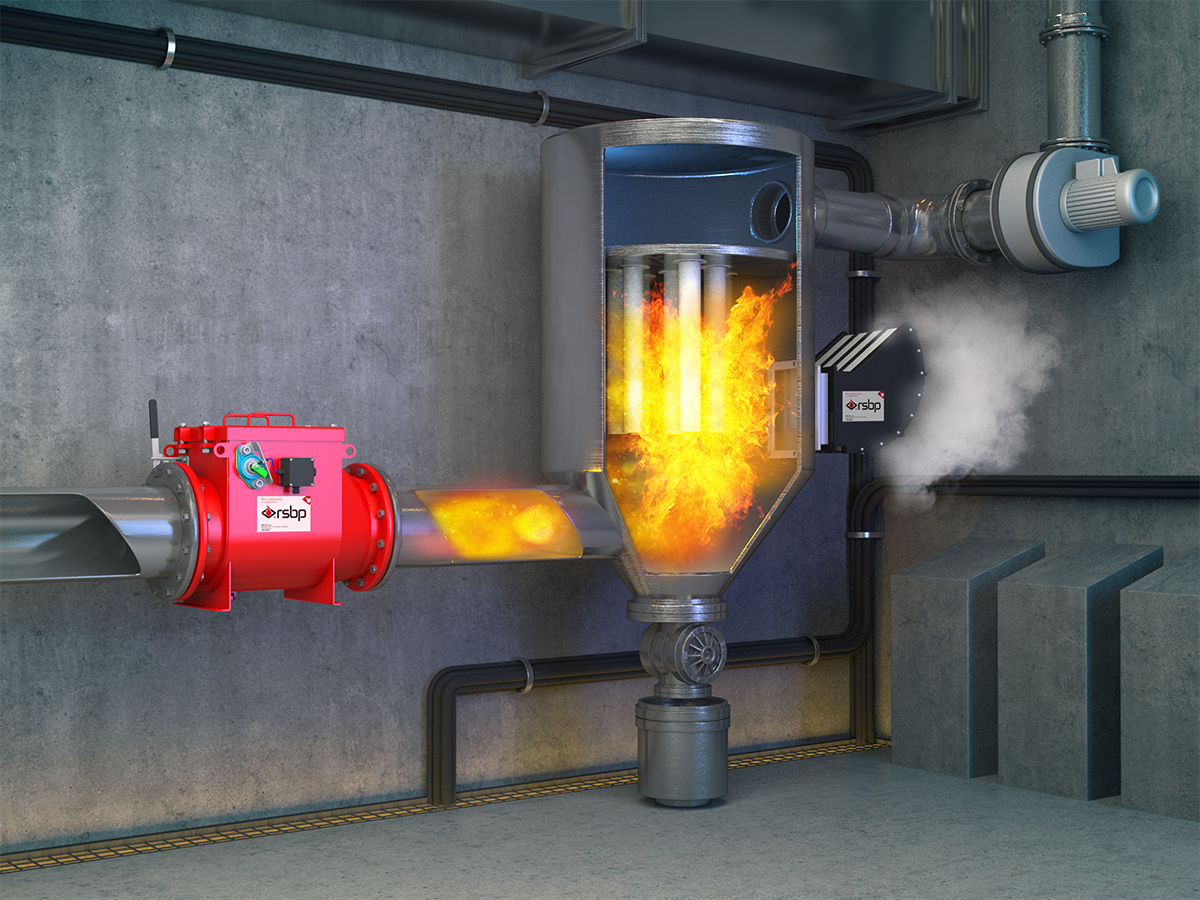

The explosion isolation flap valve B-Flap I is a suitable solution for most industrial plants that process organic or inorganic material, including dusts with low values of minimum initiation energy (MIE) and temperature (MIT).

When an explosion occurs, the flame and pressure wave is created and expand in pipes at high speed. A pressure wave hits the closing booster of the B-Flap I. An integrated locking mechanism locks the flap valve in the closed position, which prevents possible reopening due to turbulence caused by an explosion in a closed pipe. The technology itself, in this case, the filtration unit, is protected by a Flex - flameless explosion venting device. The combination of these elements guarantees maximum protection and minimum damage.

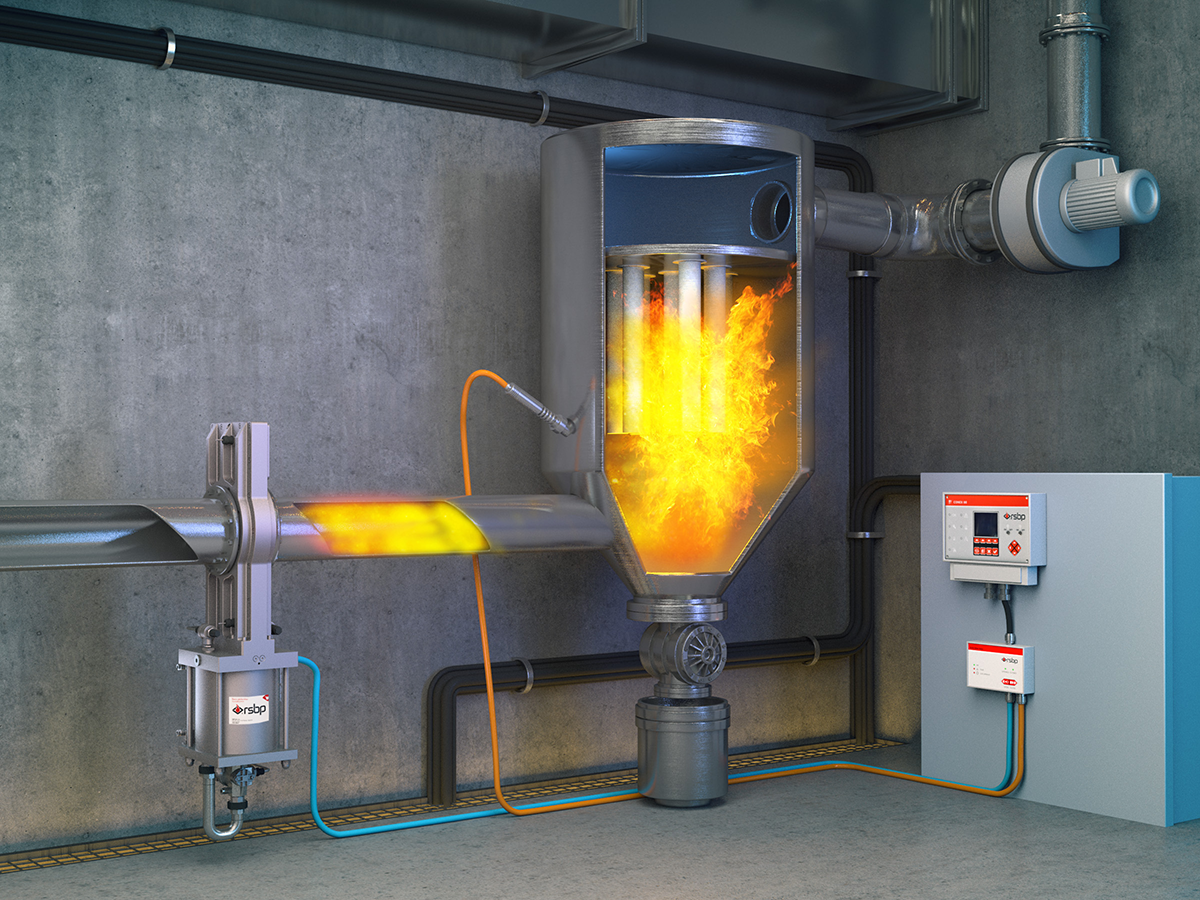

The quick-acting slide valve GatEX can be installed alongside technologies designed for maximum explosion pressure. Thanks to the pressure resistance of up to 21 bar, we can use GatEx in operations with different dust types with high values of explosion parameters.

It is also suitable for technologies processing light metal dusts. Thanks to its design, it can be used in pneumatic transport or extraction systems. It is suitable when a very short installation distance is required or in a case where pipes with a small diameter (DN 50) are installed. The GatEx closes pneumatically when an explosion is detected in the units of milliseconds.

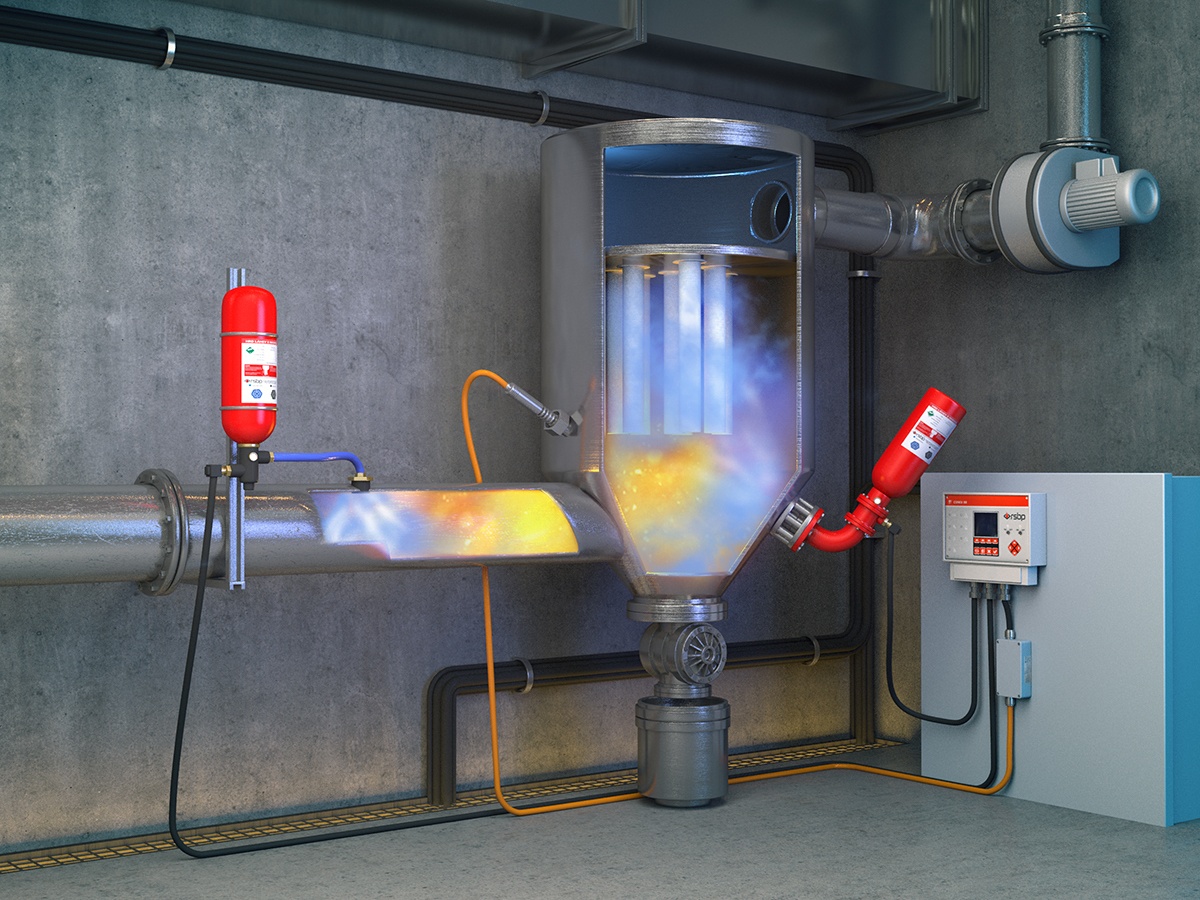

Chemical isolation works on the principle of extinguishing using a powder barrier, which prevents the transmission of the explosion to the related technology. The HRD barrier system consists of optical and pressure detectors that constantly monitor protected technologies. During the incipient explosion, the detectors send a signal to the control unit, which activates the HRD container units. These are equipped with quick-opening valves capable of immediately releasing the extinguishing agent into the protected space and thus creating an effective barrier of the extinguishing medium.

The HRD barrier can be installed in operations with increased sanitary requirements. The HRD barrier suitably complements the HRD system or devices for explosion venting or flameless explosion venting, thus creating a comprehensive explosion protection system.