This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

An explosive atmosphere can form in various places in wood processing plants. An explosion can occur directly during wood processing, where combustible dust is produced. Other risk areas may be wood material conveying systems, including belt, screw, and other conveyors. The greatest risk of combustible dust explosion is in dust extraction systems. An explosive atmosphere is constantly present in these systems and so is the risk of explosion.

During transport and handling of wood material, dust particles are dispersed. In combination with air, these particles create an explosive atmosphere. If the explosive mixture comes into contact with the ignition source, a devastating explosion can occur. The explosion is characterized by a quick rise in temperature and pressure, which can have destructive effects on both the production technology and the health and lives of the operating personnel.

Fires and dust explosions in the woodworking industry can occur, for example, during grinding, crushing, filling containers with wood waste, dedusting, extraction, and transport of wood dust to filters and separators, grinding of varnished or otherwise treated wooden parts.

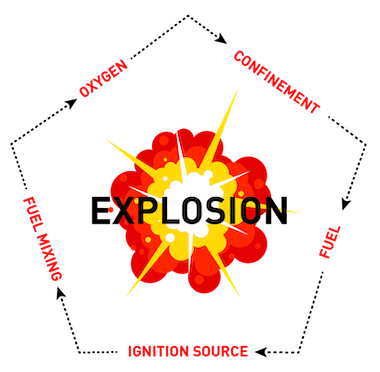

Ignition and subsequent explosion occur if the following conditions are met at the same time at the same space:

There was a fatal explosion in the Canadian town Burns Lake in British Columbia at the Babine Forest Products sawmill. The explosion and subsequent fire destroyed the factory. The cause was a high concentration of wood dust and the lack of explosion protection.

At present, it is technologically possible to identify all imminent risks in advance. The obligation to apply appropriate preventive measures is imposed by the ATEX 153 directive, which achieves the protection of human lives and production technology from the devastating consequences of an explosion.

Not sure if the issue of explosion protection also applies to your company? Are you looking for a specific solution? Contact us as experts and manufacturers who are dealing with designing suitable explosion protection on daily basis.