This website uses cookies policy in order to improve services and personalize the offer to customers in accordance with the protection of personal data. You can change the cookie settings here. Close

A dust explosion is a common threat to process industries. Over the last ten years, there have been dozens of explosions worldwide, causing deaths, injuries, and considerable financial losses for destroyed property. Cause? In most cases, it happened because of the ignition of flammable gases, vapors, and dust. Nevertheless, the tragic consequences could be averted by using high-quality explosion protection.

The risk of explosion exists wherever all explosion conditions are fulfilled at the same time. The danger applies in particular to pneumatic material transport, bucket vertical and horizontal conveyors, filtration units, dryers, storage facilities for bulk and powder materials (silos, tanks), mills and crushers, machining equipment, where materials from light metal alloys (aluminum, magnesium, etc.) are split up and spouted during the procedure.

You cannot eliminate risk of an explosion, but you can minimalize the consequences

An explosion occurs when combustible dust dispersed in the air in high-enough concentration accumulates within an enclosed location in the atmosphere or in the presence of an oxidizing agent (pure oxygen). The last requirements are a source of ignition in a given space and at given time. The explosion is characterized by the rapid production of large amounts of heat, flue gases, and an enormous increase in pressure. That leads to a blast wave and usually to the destruction of technology. The lives and health of employees are at risk, production is interrupted or stopped. Repair of damages is expensive and often time-consuming.

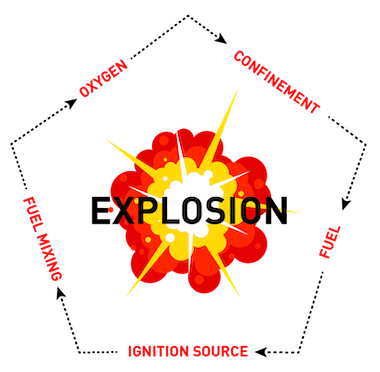

Dust from organic and most synthetic materials and metals is flammable and can explode. The risk of explosion applies to all industrial plants that process and handle bulk solids and powder materials. Explosion conditions are displayed in an explosion pentagon. To mention industries with the highest risk of dust explosion: energy and power, agricultural and food, chemical and pharmaceutical, woodworking and paper industries, metalworking, and during the application of powder paints.

In real life, it is impossible to eliminate the initiation source or explosive atmosphere. Thus most widely used protection consists of equipment designed to limit the effect of the explosion. This includes measures to reduce, suppress, and prevent the transmission of an explosion.

Explosion venting devices are used to protect against the consequences of an explosion. If an explosion occurs in an industrial plant and the explosion pressure reaches the maximum value, the explosion venting devices open automatically. The pressure in the technology drops to a safe level. Thanks to this, industrial technology will not be destroyed. The most common protection of this kind are VMP venting panels or devices for flameless venting - FLEX.

Another method of explosion protection is suppression. The HRD system detects explosion and activates extinguishing agents in milliseconds to suppress the explosion. The system reduces the explosion pressure inside the device to a level at which the technology won't be destroyed.

Explosion transmission protection devices are systems for preventing the transmission of explosions to related parts of the technology. Both passive (explosion isolation flap valve B-FLAP I) and active variant (quick-acting slide valve GatEx and HRD barrier) should be used.

ELEVEX is a certified effective solution for the explosion protection of vertical and horizontal conveyors. The ELEVEX system reduces the explosion pressure to an extremely low value. Installation of the ELEVEX system does not prevent an explosion in an elevator or other similar transport system, but the outcomes can be reduced to a minimum.

To achieve the most effective protection, RSBP highly recommends combining individual types of protection. Such a solution is especially useful in high-risk areas in which is a significant danger of technology destruction, injury, or death.

Do you want to learn more about the risk of explosion or find out about the most suitable explosion protection? Contact us.